Engineered Materials

Marvite™ Materials

Engi-Mat’s magnet wire insulation & motor resin – a proprietary family of products known as Marvite Materials – offer dramatically improved thermal conductivity, enabling increased power density, higher efficiency, and longer life for motors, actuators and related products.

Marvite wire insulation and Marvite motor resin both demonstrate high thermal conductivity. In solenoid coil tests, Marvite Materials provided a dramatic improvement in heat dissipation, enabling 46% more power without increasing wire temperature (or 31% lower temperature rise at the same power). Additionally, Marvite wire insulation has a thermal index of 281°C.

Additional information about Marvite Materials is available here.

Functional Surfaces

Engi-Mat has developed a proprietary process to provide high-performance coatings for various substrates as illustrated below.

Superhydrophobic

The combination of low surface energy and nano-structured features enables the superhydrophobic performance of the surface. Water droplets coming in contact with a superhydrophobic surface will form nearly spherical beads (see images) with a water contact angle above 150°.

Superhydrophobic surfaces are often referred to as self-cleaning. Any contaminants, either inorganic or organic, on such surfaces are readily picked up by water droplets and removed from the surface when the water droplets roll off.

Superhydrophilic

Whereas water on a superhydrophobic surface has a high contact angle, water on a superhydrophilic surface will have a contact angle that approaches zero degrees. There are several benefits of this interaction. For example, since beads of water do not form, the natural evaporation process does not produce water marks on the glass surface as it would with normal glass. Additionally, superhydrophilic surfaces can have anti-fogging properties, as it takes longer for glass droplets to reduce visibility.

Water on Engi-Mat’s superhydrophobic glass

Functional Surfaces: Engi-Mat goes to Mars

Superhydrophobic fabric developed by Engi-Mat provides an exceptional level of self-cleaning performance. As a result of earlier research conducted with the support of NASA, Engi-Mat’s coated fabric is being considered by NASA for incorporation as an outer layer of future Thermal Micrometeoroid Garments (TMGs), which would be employed on the moon or Mars.

As part of this effort, Engi-Mat’s superhydrophobic fabric will travel to Mars on the next Rover mission, which is scheduled for launch in July of 2020. During the Rover mission on the planet surface, the performance of the fabric will be assessed in a variety of ways after exposure to the Martian environment.

The link below provides additional information.

Engi-Mat’s proprietary coated fabric will travel to Mars on the next rover mission.

Customizable Ceramic-on-Metal Coatings

Engi-Mat has developed a novel Flame Assisted Flash Sintering (FAFS) technology for ceramic-on-metal surfaces. The FAFS process provides value in diverse applications where ceramic coatings are applied to metal, from heat exchangers and thermal barrier coatings to fuel cells and aerospace applications.

FAFS is a breakthrough technology enabling rapid sintering of ceramic to metal with dramatically improved adhesion and hardness. Engi-Mat’s patented FAFS process enables control of:

- Density

- Adhesion

- Porosity

- Hardness

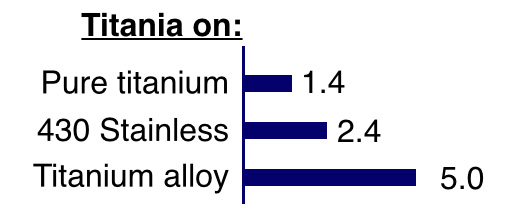

Increased Hardness and Adhesion

FAFS’ high ceramic-to-metal adhesion far exceeds that of thermal spray techniques. Vickers hardness estimates (GPa) are as follows:

Proven broad material capability

- Coatings include YSZ, YAG, LSM, TiO2, HAP, and various composites

- Substrates include Titanium, SS, Aluminum, and Nickel625

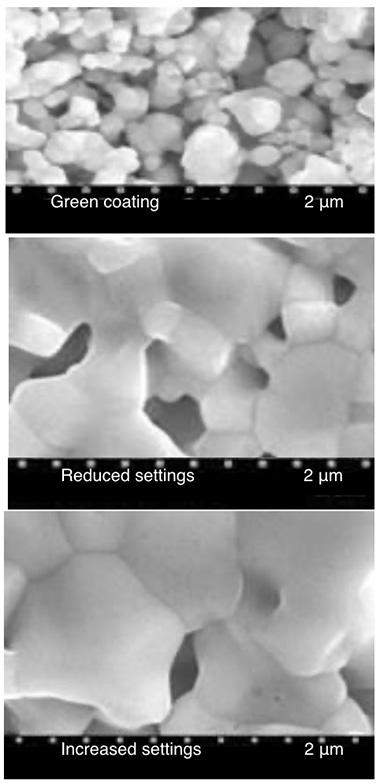

Optimization of Thermal Conductivity

Density/porosity can be closely controlled to maximize or minimize heat transfer as required. SEM images of YSZ on SST shown above.